We are leading manufacturer & supplier of Lined Dip Pipe in India

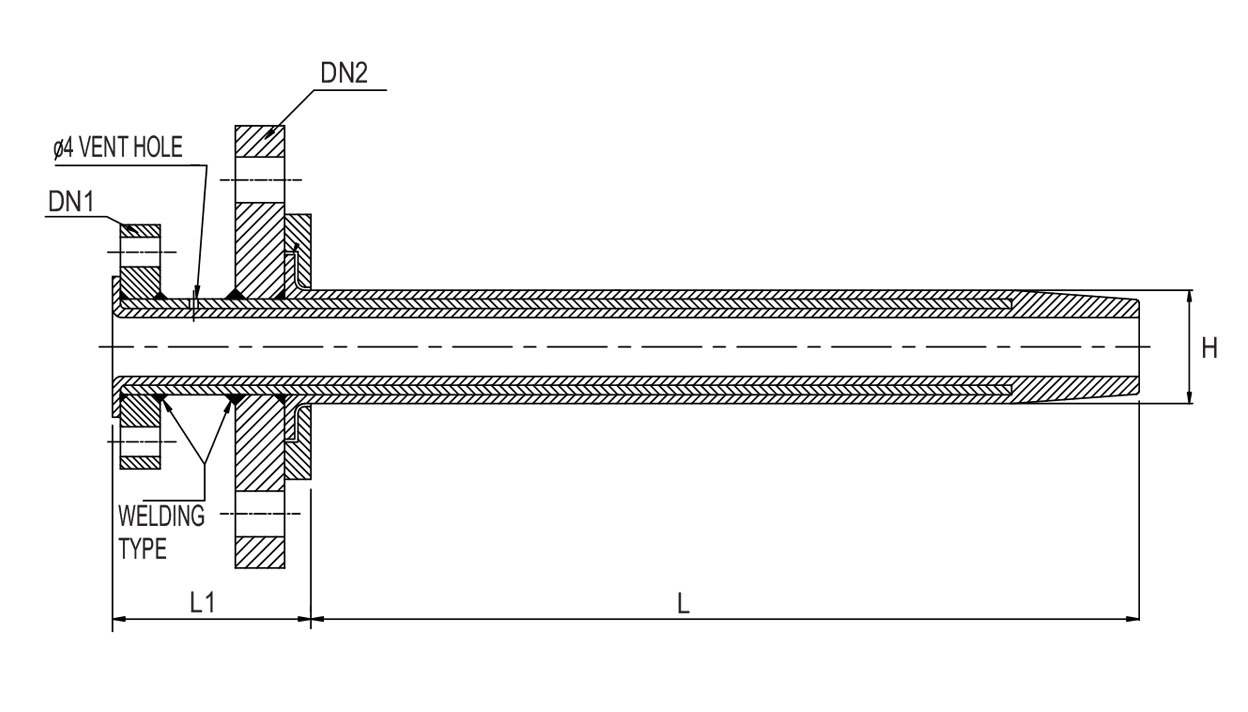

Click on Image to Enlarge Ask PriceOur PTFE Lined & Jacketed Steel Dip Pipes & Spargers are manufactured to the highest standards in the industry. Units are given extreme stress tests to validate the integrity and long life. Flared sealing of joint is provided with machined PTFE seal – plate of uniform thickness and surface finish which ensures higher seal integrity over the uneven sealing surface of a flare. Sparger extensions are solidly fused to the liners and jackets and are smaller in diameter to fit various CPI applications. These extensions can be straight, angular, and PH Probe adapter. Our standard sch. 40 seamless steel pipes conform to grade ASTM A 106 Group B. We can make closed-end dip pipes with tantalum tips for thermowell & reinforced baffle applications.

| Pipe Nominal Bore / Process Flange Size (NB) | Face to Face (F) Min. | Total Length (L) Max. | PTFE Liner Thickness | Pipe Schedule | Vessel Flange Schedule | NB Min’m Inlet Nozzle ID | ||

| (mm) | (inches) | (mm) | (mm) | (mm) | (mm) | Min. (mm) | Max.(mm) | (mm) |

| 25 | 1 | 60 | 3000 | 2.5 | 40 | 40 | 600 | 45 |

| 40 | 1.5 | 70 | 3000 | 2.8 | 40 | 50 | 600 | 60 |

| 50 | 2 | 75 | 3000 | 3.0 | 40 | 80 | 600 | 73 |

| 80 | 3 | 85 | 3000 | 3.0 | 40 | 100 | 600 | 101 |

| 100 | 4 | 90 | 2800 | 4.5 | 40 | 150 | 600 | 130 |

PRODUCT FEATURES

- All wetted parts PTFE Lined, giving optimum corrosion resistance

- Liner Construction : Single piece, past extruded PTFE

- Carbon Steel construction providing good mechanical strength

AVAILABLE DIP PIPE

- Lined Dip Pipe with Sparger

- Lined Slanted ( Angular ) Dip Pipe

- Lined ‘ J ‘ type Dip Pipe

- PTFE solid ‘ J ‘ type Dip Pipe

- Solid PTFE & PTFE Lined Feed Pipe for Columns

HOUSING MATERIAL

- Pipe : ANSI B 36.10, ASTM A 106 Gr. B Schedule 40

- Flanges : ANSI B 16.5 ASA 150 # , ASTM A 105

- Liner : PTFE in accordance with ASTM D 1457

OPTIONS

- Flange : Fixed/Rotating,PN 10/16, BS 10,

- Table D/E

- Extras : Earthing Studs/Lugs, Vent Extensions

- Liner : PTFE

DESIGN SPECIFICATION

- Flange : As per ANSI B 16.5/B 16.42

- Face to Face : As per ANSI B 16.5 # 150

- Lining Thickness : 3 to 5 mm

Other Flanges Drilling like DIN 2632/2633, BS 10 Table D, E or F are also available on request

TEST & INSPECTION DATA

Resins are conforming to the requirements of ASTM F 1545-97(2003)

- Hydraulic Test : 20 Kg/Cm2 After Lining

- Spark Test : 15 KV D.C After Linin

FEATURES

- Unique jointless PTFE construction for prolonged service

- G Perfectly suited for vessels with agitator

- G Angular spool option for tilting upto 20 deg.

- G Unique jointless PTFE construction for prolonged service

- G Proven performance in various industries

- PP/HDPE lining with weld joint at bottom also available on request

Make Enquiry